09. Dezember 2025

Two experts, one mission: HB-Therm & Iftest in perfect harmony

HB-Therm offers first-class temperature control solutions and has a long-standing partnership with Iftest, characterized by mutual trust and the highest quality standards. The clear division of roles strengthens the efficiency and innovative power of both companies.

HB-Therm AG was founded in 1967 and is considered a global pioneer in the manufacture of temperature control units primarily used in plastics processing. The company combines innovation, precision, and sustainability. The precise temperature control of the temperature control units is achieved through dedicated HW in combination with suitable embedded SW. This reduces energy consumption and wear, increases flexibility and service life, and shortens amortization times.

The company has a particularly strong market presence in Switzerland and is regarded worldwide as a leading manufacturer of temperature control units. Its declared market leadership is based on consistent quality standards, which are underpinned by “Swiss Made” production, as well as on the continuous development of technological solutions and the cultivation of long-term customer relationships.

For its temperature control units, HB-Therm requires reliable electronics. Iftest specializes in the development, manufacturing, and testing of control electronics. These clear roles complement each other perfectly: HB-Therm provides the mechanical and application-specific expertise in temperature control technology, while Iftest provides the robust electronic basis, developed, industrialized, and ready for series production.

Both companies stand for precision and durability. Through jointly defined quality standards, supported by ISO certifications, create trust in every step of the process – from development and pilot series to series production and beyond.

Both companies benefit from their geographical proximity: there are fewer logistical hurdles, easy coordination and a shared language and culture. This facilitates planning, production and support. An open exchange in development, prototyping and series production shape everyday collaboration. Short decision-making processes and clear contact persons ensure that projects progress in a targeted and efficient manner. Stable supply chains and punctuality to delivery dates strengthen mutual trust. The partnership thrives on reliable cooperation, from procurement to delivery.

HB-Therm continuously develops its devices, from energy-efficient control technologies to digital and user-friendly features. Iftest implements new electronic solutions promptly, ensuring smooth updates and cutting-edge solutions.

The success story of HB-Therm and Iftest impressively demonstrates how complementary competencies, common quality standards, and an open and long-term partnership can create sustainable value. This partnership is a prime example of practical cooperation in the high-tech industry.

“In our partnership with Iftest AG, the most important factors for us were an excellent price-performance ratio, strong strategic purchasing, the size of the development team and cost-optimized manufacturing options (production site in Slovakia). The collaboration was based on partnership, and Iftest always had an open ear for our concerns.”

Martin Braun, CTO HB-Therm AG

The evolution of temperature control units from Series 3 to 6

Across all series, process stability, energy efficiency, and connectivity have continuously improved: Control has been fine-tuned, sensors deliver higher accuracy, and modern interfaces enable seamless integration into higher-level machine controls and comprehensive process data acquisition. At the same time, the developments aim to improve user-friendliness, extend maintenance intervals, and increase the overall availability of components. The first collaboration with Iftest AG took place during the fourth generation of devices (Series 4, 1998/1999), in which the electronics for the device interface (GIF) were developed.

The Series 5 added the USR controller and circuit boards for various data interfaces. For the first time, the scope of services now includes not only hardware, but also complete software development and production.

The current Series 6 now includes the Gate-6 in addition to the Thermo-6 temperature control units. This not only functions as an interface server but also opens the door to the digital world for temperature control units for the first time. It enables connection to the machine control system via mobile devices and access to numerous digital services. Iftest impressed with its expertise and experience and was involved in:

› Supporting technical concept development

› HW design based on the proven Iftest Carrier-Boards

› Layout (according to Design for Excellence methodology)

› Specific test concept

The Gate-6 can be used flexibly to enable good visualization and convenient remote control. This makes operation, management and analysis much easier.

Digital integration is achieved through the “e-cockpit app” from HB-Therm, which enables:

› Remote control via smartphone or tablet

› Access to Thermo-6 from anywhere

› Live support from HB Therm

› Transmission of analysis data at the touch of a button

Gate-6 and the “e-cockpit” app are the concrete answer to today’s needs and future challenges in the digitalization and connectivity of manufacturing.

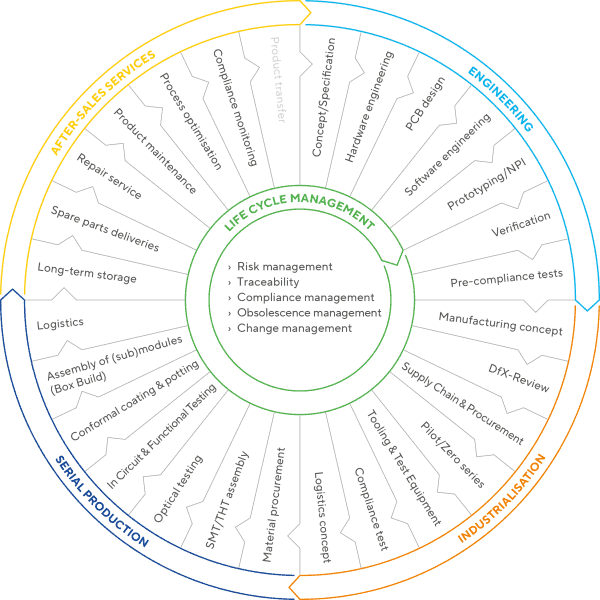

Added value through a comprehensive range of services

In summary, Iftest offers its customer HB-Therm comprehensive added value through integrated development, production and after-sales support:

› Comprehensive product development: From the idea to the design to prototype and series production. Shorter time-to-market through lean processes and close coordination.

› System efficiency and quality: Higher reliability through integrated software and hardware development, consistent testing and validation phases and standard-compliant implementation.

› Seamless integration: Optimal fit of electronics, mechanics and firmware into existing HB-Therm systems, including interfaces, communication protocols and networking.

› Customized software: Embedded software, firmware stacks, diagnostics, security features and maintenance tools (e.g., logging, telemetry, update mechanisms).

› After-sales support: Comprehensive service after market launch – maintenance, updates, troubleshooting, remote support and PCN+PDN support.

› Risk minimization: Clear responsibilities, documented processes, and a coordinated quality management system throughout the entire product life cycle.

Technical solutions

› Today’s Series 6 includes the control and regulation of flow, pressure and temperature using a modern microcontroller. The microcontrollers used are the i.MX RT1051 and the STM32L412. In addition, QuadSPI flash memory is available and communication takes place via isolated RS485 in full-duplex mode. Furthermore, temperature and pressure measurements, ultrasonic flow measurement, stepper motor control, 24 VAC and 230 VAC solid-state relays, mains current measurement and monitoring are also integrated. Other aspects include the bootloader, Modbus, MQTT and PPP, the FreeRTOS and lwIP software stacks, the heap-and stack monitoring, as well as the Error-Log.

› The control module and gateway platform displays process parameters on a screen and connects to machine controllers from different manufacturers. It uses an i.MX8 computer on module and an i.MXRT coprocessor (Cortex-M7) and has RTC, Ethernet with switch, industrial Ethernet, USB host, micro SD, Bluetooth/WiFi, LVDS for a 7″ display, buzzer, bootloader, Linux, CAN/CANopen and a TTY interface.

› We have fully implemented the safety requirements in accordance with EN 61010 and the EMC requirements in accordance with EN 61326 and integrated them into our system to ensure user safety and electromagnetic compatibility.

Services provided by Iftest for HB-Therm: hardware, drivers, and firmware – all from a single source!

› Microcontroller design: Selection and implementation of high-performance MCUs with optimized power management.

› Driver development: Creation of customized drivers for sensors, fieldbus interfaces and high-speed communication.

› FreeRTOS integration: Configuration of tasks, queues and timers for deterministic real-time behavior.

› Security and update mechanisms: Over-the-air firmware updates and robust fallback strategy.

Iftest has met all requirements – mission accomplished. We are proud to have been a competent and reliable partner to HB-Therm for many years and look forward to many more exciting projects.

With Iftest, you get a customized solution and an unbeatable ratio of development to unit costs. Let yourself be surprised by the potential of a future-proof collaboration and get in touch with us.

Sales & Business Development

Peter Traub

Tel +41 56 437 37 19

peter.traub@iftest.ch