28. September 2018

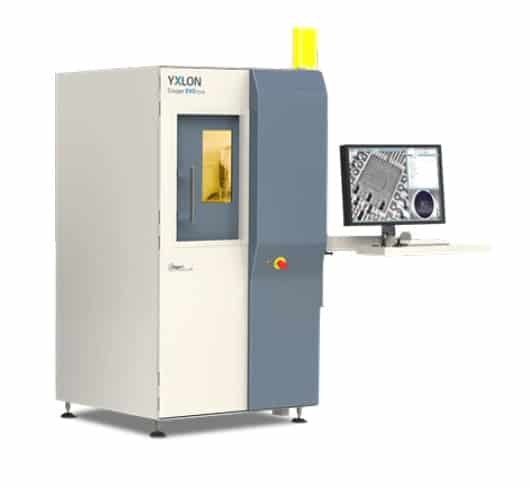

X-ray microscope for enhanced process monitoring at Iftest

Since May 2018, Iftest has been using a new-generation x-ray microscope to enhance quality assurance and process monitoring in electronics manufacturing. The addition complements the existing quality assurance tools, such as the 3D Automated Optical Inspection (AOI) system and a series of other electronic testing techniques, to provide customers with guaranteed top-quality products.

The use of an x-ray microscope with a lateral resolution of one micrometre enables even better visualisation of structural details through a higher resolution and greater depth of information. This is essential for the efficient detection and assessment of non-visible soldering joints, for example. As a result, the x-ray microscope is particularly helpful in the testing of components such as ball grid arrays (BGA) and micro lead frames (MLF), as joints tend to be fully or partially covered in these types of component structures.

At Iftest, the x-ray microscope accomplishes several tasks during quality assurance:

- Diagnostics tool in process development as a preparation for serial manufacturing of newly introduced products

- Carrying out random testing for quality assurance purposes

- Diagnostics tool in root cause analysis; a systematic root cause analysis is used to develop and implement concrete corrective action measures

Learn more about test engineering at Iftest

Massimiliano D'Amore

Tel allg. +41 56 437 37 37

massimiliano.d'amore@iftest.ch