19. August 2025

Increase in energy efficiency thanks to smart engineering

The challenge

The customer was faced with the task of bringing the ECO RO Dia I/II Systeme plant, dating from the year 2000, up to the latest technical standards. The existing control system – developed by Iftest AG – had reliably fulfilled its purpose for many years, but was now technically outdated:

- No support for modern sensors and actuators

- No interfaces for networking with higher-level systems

- An aged user interface

- Foreseeable end to the availability of major electronic components

- High energy consumption, even in standby mode

- Noise emission

The solution: Systematic modernisation – with a vision

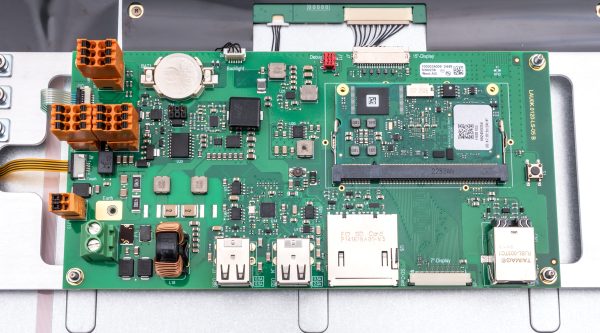

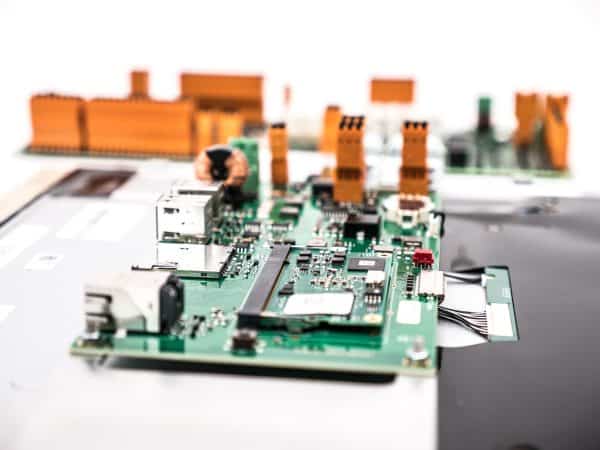

The focus was on increasing throughput, better energy efficiency, lower noise emissions and low operating costs – without fundamentally changing the proven control concept. This consists of a DIN rail module for the system controller, supplemented by a remote control module (HMI) in the front door. The basis is the proven Iftest carrier board concept.

The major innovations at a glance:

Iftest carrier board concept with integration of the system-relevant interfaces (USB, CAN, RS485, etc.)

Modern 7″ or 15″ touch HMI with graphical user interface

Linux-based i.MX6 COM module as a high-performance control platform

Ethernet port for simple connection to networks

USB & memory card for local data exchange and system maintenance

Electrically isolated sensor/actuator interfaces for precise measurement and safe control

Integration of a safety controller for monitoring safety-relevant functions

Secure update process with authorisation, fallback & logging for maximum operational reliability

Demand-driven water treatment process by the activation of frequency-controlled pumps for a further increase in efficiency

EMC robustness and safety concepts for medical products

Software development according to EN 62304 for the highest quality standards

The result

The modernised AQUABoss nX controller not only increases the system performance, but also makes it much more future-proof. The new HMI provides operators with an intuitive and visually appealing user experience. The facelift fully corresponds to the customer’s corporate design and at the same time provides for an expansion of functions. Thanks to modular connectivity, the plant is now fit for higher-level systems and future digitisation measures.

At the same time, safety controllers and EMC optimisations ensure more robust and safe operation. The introduction of a demand-driven treatment process has reduced energy consumption by up to 65%. At the same time, the water recovery rate has been increased to up to 95%, making the plant not only more environmentally friendly, but also cost-saving – entirely in the spirit of efficiency, sustainability and safety.

Source: B. Braun

Discover the world of IFTEST!

Discover the future of tailor-made solutions with IFTEST’s innovative carrier boards! Just imagine being able to use a modular carrier board concept that is perfectly tailored to your specific applications! With Iftest, you not only get an individual solution, but also an unbeatable ratio between development and unit costs. You will be surprised by the possibilities that future-proof technology offers you!

Sales & Business Development

Peter Traub

Tel +41 56 437 37 19

peter.traub@iftest.ch